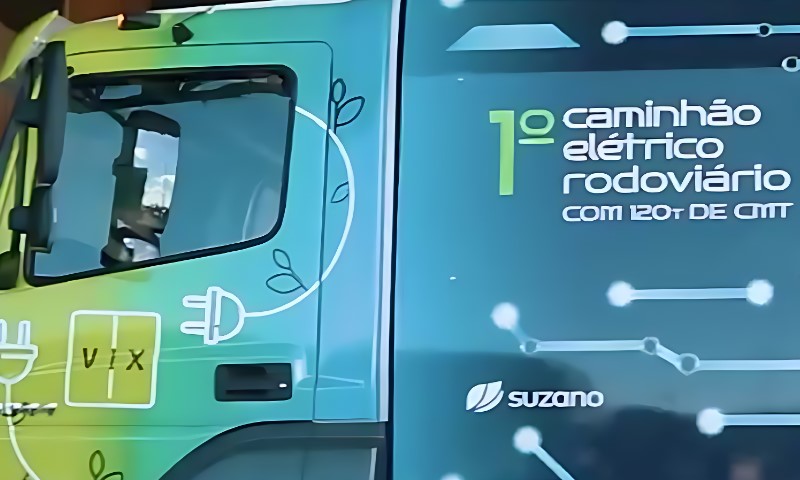

Brazil has just rolled out an electric workhorse unlike anything the region has seen before. The Atlas electric truck, developed for ultra-heavy industrial logistics, is now operating at Suzano’s massive pulp and paper complex in Espírito Santo.

Partnered with VIX Logística, Suzano is testing the vehicle’s ability to tow extraordinary loads while slashing diesel use and carbon emissions.

Early numbers suggest the truck can avoid around 21 tons of CO₂ every month on select routes, putting it in a league of its own for Latin American freight.

A Quick Snapshot of the Atlas Project

What Atlas Actually Is

View this post on Instagram

Atlas is not a mass-produced commercial model.

It is a custom VIX-developed conversion built for high-capacity industrial moves, integrated into Suzano’s operations to test feasibility at scale.

Key details from public sources:

- Base platform: Mercedes-Benz Axor 3344 chassis.

- Electric powertrain: Custom installation with lithium iron phosphate (LFP) batteries.

- Battery capacity: About 200 kWh cited in local coverage.

- Motor output: Roughly 450 kW traction motor.

- Operational autonomy: Claimed up to 16 hours within its targeted duty cycle.

- Load rating: Up to 120 tonnes combined mass for site operations.

This setup positions Atlas far beyond the capacity of a typical Brazilian road tractor. For comparison, most highway rigs operate around 40 tonnes combined.

The Atlas configuration is tailored for closed-loop industrial logistics rather than public highway use.

Why the Duty Cycle Matters

Atlas runs short, heavy routes inside or near Suzano’s Aracruz plant.

By staying on fixed loops, it avoids the uncertainty of public charging and can be topped up frequently.

That is how a relatively small 200 kWh battery can support such a demanding workload.

It is a strategy designed around charging convenience and predictable distances rather than highway endurance.

Breaking Down the 21 Tons per Month Claim

VIX and Suzano repeatedly cite two numbers:

- Up to 8,300 liters of diesel saved per month.

- Around 21 tons of CO₂ avoided per month.

A standard emission factor for diesel combustion is roughly 2.64 to 2.70 kg of CO₂ per liter at the tailpipe.

Multiplying 8,300 liters by 2.64 kg gives about 21.9 tons of CO₂ monthly. That lines up with the figure being reported by Suzano.

It also suggests the partners are using conservative assumptions or netting out the carbon intensity of electricity to present a rounded number.

Key point: the numbers are route-dependent. Load factors, gradients, dwell times, and power availability all change the calculation. But the math itself is credible by international standards.

How We Can Check the Math

- Diesel avoided: 8,300 liters × 2.64 kg CO₂ per liter = 21,912 kg CO₂.

- Result: ~21.9 tons of CO₂ per month avoided.

Even if Brazil’s grid contributes some CO₂ per kWh, it is relatively low compared with global averages because of the country’s high share of hydropower and other renewables.

That makes the net benefit larger than in a coal-dominated grid.

The Policy and Market Context Behind Atlas

Atlas did not appear in a vacuum. Its debut reflects shifts in Brazil’s freight policies, emissions standards, and a market slowly warming to heavy electric trucks.

Emissions Standards Getting Tougher

Brazil’s PROCONVE P-8 standard, which began phasing in during 2022, aligns heavy-duty engines with Euro VI pollutant limits.

While the regulation focuses on local pollutants such as NOx and PM rather than CO₂, compliance costs for diesel engines are rising, making zero-emission trucks more attractive in high-utilization niches.

Electric Trucks Taking Off from a Small Base

Brazil’s electric truck market is still at an early stage. According to the International Energy Agency’s Global EV Outlook 2025, nearly 500 electric trucks were sold in Brazil in 2024.

Most were medium-duty models like Volkswagen’s e-Delivery or demonstration units from Volvo.

Atlas carves out a new corner: ultra-heavy industrial haulage where predictable routes and on-site charging can make electrification viable sooner than on the open road.

Charging Infrastructure Expanding

Public charging growth is not central to the Atlas pilot because charging happens inside Suzano’s industrial site.

Still, the broader expansion of charging infrastructure in Brazil supports multi-site planning and shared investment.

Multiple trackers show station counts rising quickly between 2024 and 2025.

Technical Snapshot at a Glance

Caveats Worth Noting

- The 200 kWh battery is modest compared with highway tractors in Europe or North America, which often carry 300 to 900 kWh. The difference reflects Atlas’s duty cycle.

- The 120-tonne rating applies to specific industrial configurations and routes, not general highway travel.

- Publicly available data does not yet show detailed kWh per cycle or per ton-kilometer.

Why Suzano and VIX Are Pursuing Atlas

They are testing a strategy. Suzano and VIX see Atlas as a way to cut emissions, gain operational control, and learn how electric heavy haulage can work in Brazil’s toughest industrial conditions.

Operational Control

Suzano’s pulp operations move massive volumes between production lines, warehouses, and port interfaces. Those flows are highly scheduled and repeatable.

That environment is perfect for early electrification because operators can install chargers where they need them, manage shift breaks around charging, and tune routes to battery performance.

Corporate Climate Targets

Suzano publishes extensive sustainability reporting. The company tracks Scope 1, 2, and numerous Scope 3 categories, including upstream and downstream transport.

Introducing an electric heavy hauler at a flagship mill directly supports those commitments.

Choosing low-resistance Hubtrac tires alongside electric drivetrains further boosts emission savings.

Technical Learning and Vendor Development

For VIX, the project builds capabilities in heavy EV conversions and systems integration.

It also helps Brazilian suppliers and service networks learn how to maintain high-power electric drivetrains in demanding conditions.

The pilot creates a domestic knowledge base for future scale-up.

Practical Insights for Fleet Operators Watching Atlas

Here are some quick, straight-from-the-field tips for fleet operators sizing up heavy electric trucks.

1. Start Where the Math Works

Short, repeatable, heavy moves inside plants or between fixed yards tend to deliver the best returns for electric heavy vehicles.

You can right-size battery packs, exploit regenerative braking, and schedule opportunity charging. Atlas applies that playbook.

2. Control Your Electrons

Industrial sites can co-site charging with existing electrical infrastructure.

If your electricity supply is partially renewable, your well-to-wheel emissions fall further than tank-to-wheel comparisons suggest.

Suzano benefits from Brazil’s high renewable share in its power mix.

3. Use Conservative Carbon Math

Stakeholders scrutinize emission claims. Publish:

- Baseline diesel consumption per route.

- Emission factor used for diesel.

- Grid emission factor for the electricity used.

- Any adjustments for idle reduction or load factors.

4. Build Maintenance Pathways Early

High-power drivetrains, high-voltage safety, cooling, and power electronics need trained technicians.

VIX’s emphasis on thermal management, suppression, and pack containment shows a pragmatic approach to uptime and risk mitigation.

5. Watch Technology Pipelines

Brazilian players are testing fast-charge chemistries such as lithium-niobium cells aiming for very short charge times and long cycle life.

If those reach production, they could shift the economics of heavy electric duty cycles.

How Atlas Compares to Other Electric Trucks in Brazil

Limitations and Open Questions

- Public data on energy use: Exact kWh per cycle and per ton-kilometer are not disclosed. Publishing would help model ROI.

- Charging power and schedule: No public data on charger size or duty cycle timing. For a 200 kWh pack, on-site DC charging above 150 kW would be practical, but details are not released.

- Scale-up pathway: It is unclear whether the plan is to convert multiple chassis, transition to a production supplier, or license components.

Why the Atlas Pilot Still Matters Even If It Is Niche

Heavy industrial logistics often sets the tone for the broader freight market. When high-capacity moves begin to electrify, it proves three things:

- Torque and tractive effort are achievable: Electric motors can meet or exceed diesel performance in controlled environments.

- Charging strategy beats raw battery size: Many site-based applications do not need highway-scale batteries.

- Emissions reductions add up quickly: At 21 tons CO₂ per month, even a small fleet can rack up meaningful annual savings. Two trucks could avoid over 250 tons of CO₂ per year, depending on route variability and grid factors.

Policy and Market Signals to Watch

- PROCONVE P-8 enforcement and future CO₂ rules: Stronger enforcement raises diesel costs and pushes zero-emission technology.

- Industrial site electrification programs: More mills, ports, and mining sites are installing high-power DC charging and testing heavy EVs.

- Market adoption data: The IEA count of about 500 electric truck sales in 2024 is a baseline to beat as domestic makers expand offerings.

- Charging build-out: National counts vary, but the trajectory is upward, reducing perceived risk for fleets.

Takeaways for Sustainability Teams

- Target high-impact internal routes first: Copy the Atlas playbook if you run mills, mines, or ports. Focus on short routes, heavy loads, fixed schedules, and on-site charging.

- Design around the duty cycle: A 200 kWh pack can be enough if you control stops and charging windows.

- Plan skills and safety early: Invest in technician training, battery thermal management, and incident response.

- Engage your power provider: Explore dedicated feeders, demand management, and on-site generation to stabilize costs.

- Use pilots to shape procurement: Real-world data helps specify future equipment and negotiate service levels.

Final Thoughts

Atlas is not designed to conquer the highways of Brazil just yet. It is built to handle an even harder problem: moving extraordinary loads in a tightly controlled industrial environment.

By targeting 8,300 liters of diesel avoided and about 21 tons of CO₂ saved per month, the pilot sets a credible benchmark for heavy electrification in Latin America.

As Brazil’s emission standards tighten, charging networks grow, and battery technology improves, projects like Atlas can expand from one-off pilots to mainstream fleets.

The lesson for operators everywhere is clear: start where electrification makes the most sense, build the expertise in real conditions, and let the results speak for themselves.